Description

▶ Brief introduction of QTF4-24 interlocking brick machine.

QTF4-24 can produce hollow and solid blocks of different sizes and shapes by changing the mold.

- High yield and high efficiency

The forming cycle of QTF4-24 is 24s, and the production efficiency is very high. Each class can reach 2880-3600 bricks (8 hours), and the production capacity varies according to the size and type of bricks.

- Advanced technique

The machine adopts vibration molding technology, which makes the working state of the brick-making machine more stable and efficient, and produces better brick quality, higher density and higher strength.

- High quality mold

We use high quality steel as raw materials, through advanced wire cutting and carburizing heat treatment process meticulous production, in the strong wear has great advantages.

▶ Main technical parameters of QTF4-24 rammed concrete brick making machine.

| Dimension of host machine | 2060*1730*2580mm | Voltage | Adjustable |

| Shaping cycle | 24s | Host machine power | 13.45kw |

| Vibration force | 35.5KN | Weight of the machine | 3T |

| Applied products | hollow, solid and paving blocks | Raw material | Soil/Sand/Cement |

| Pallet size | 850*550*30mm | Mixer model | JQ350 |

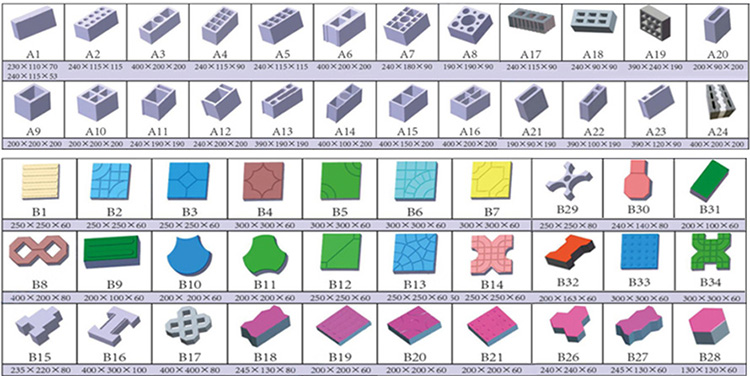

▶ Brick mould sample

The following bricks shapes are the commom shapes, besides, we can design for you according to your special requirement.