Description

QTF4-25D is hydraulic automatic concrete hollow block manufacturing machine, a fully automatic production line consisting of special cement mixer, belt conveyor, PLC control system and main machine.

♦ 1. Main machine consists of electromagnetic valves, hydraulic cylinder, hydraulic oil circuit cooler system, molding system. All these key components work in coordination under the control of imported PLC control system.

♦ 2. Alloy steel parts and special welded joints make this machine more durable and stable.

♦ 3. The machine adopts 360° rotating material feeding technology, which is quick and uniform.

♦ 4. User-friendly operation interface, easy operation. Advanced fault automatic diagnosis system, avoids damage caused by misuse.

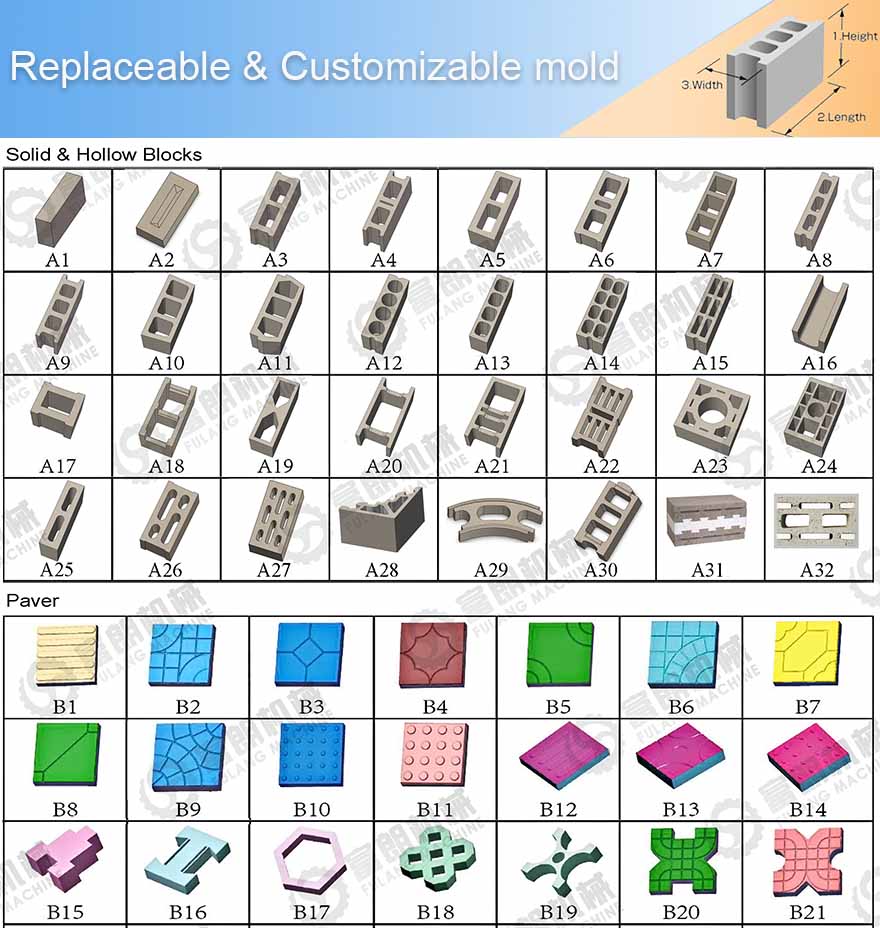

♦ 5. By replacing of the mold, this machine can produce hollow blocks, standard bricks, pavement bricks, curbstones, and secondary color feeding devices can be equipped to produce colored pavement bricks. This machine is one high-tech production in collecting electric, liquid, vibration.

Host machine main technology parameter

| Dimension | 3700x2100x2300mm | Weight | 3Ton |

| Shaping cycle | 15~20s | Vibration foce | 35.5KN |

| Host machine power | 16.35KW | Mixer model | JQ500 |

| Pallet size | 850x550x30mm | Certification | CE&ISO |

Production requirement

| Total area | 2000m2 | Workers needed | 3~4 person |

| Workshop | 50m2 | Distribution power | 26KW |

| Raw material store workshop | 300m2 | Water consumption | 4Ton/day |

| Office area | 30m2 | Pallet quantity | 1200 |

Installation abroad

There are no complicated links in machine installation, so many of our customers who have their own engineers can install the machine themselves. And we can also send our engineers to install the machine in your country according to your requirement.

There are no complicated links in machine installation, so many of our customers who have their own engineers can install the machine themselves. And we can also send our engineers to install the machine in your country according to your requirement.