Description

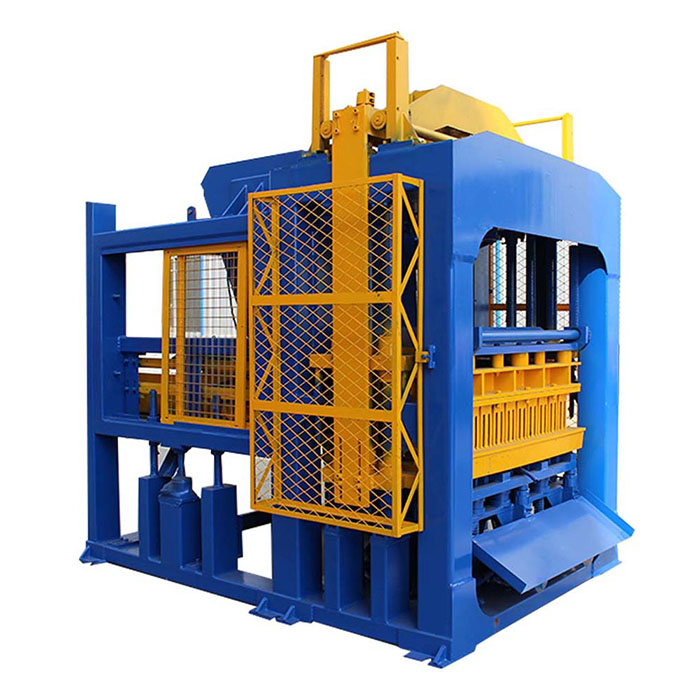

Machine description

- PLC control system:The equipment adopts PLC automatic control system. It only needs 3-4 people to operate the whole production line and complete the production of finished bricks. It greatly reduces the cost of labor in investment. It reduces the degree of manual work and improves the efficiency of work.

- Environmental protection mechanism:In the production of this equipment, it can be said that the environmental protection production has been achieved completely. It does not need the old brick kiln to roast, and the use of various waste mixtures has a good effect on reducing the cost.

- The raw materials are extensive:The raw materials of fly ash, sea sand, mountain sand, River sand, ore powder, slag and so on can be used to produce unburned bricks.

- Structure advantage:The equipment has the characteristics of compact structure, strong rigidity, high pressure, fully sealed dustproof, cyclic lubrication, high output, simple operation and durability.

- Advanced molding technology:Efficient hydraulic pressing and vibration system to ensure high quality and strength of products. The unique rotary cloth device has novel structure, uniform cloth, beautiful appearance, no noise and fast speed.

- High quality mold:Brick molds are made of special wear-resistant steel to ensure long-term use and effectively reduce the cost of die wear.

Main technical parameters

| Dimension of host machine | 3500x2300x2930mm | Power of host machine | 37KW |

| Weight of host machine | 9.8T | Pressure force | 100KN |

| Water consumption | 10-20T/Day | Pallet size | 1300x900x30mm |

| Molding area | 1196x880mm | Mixer model | JS750 |

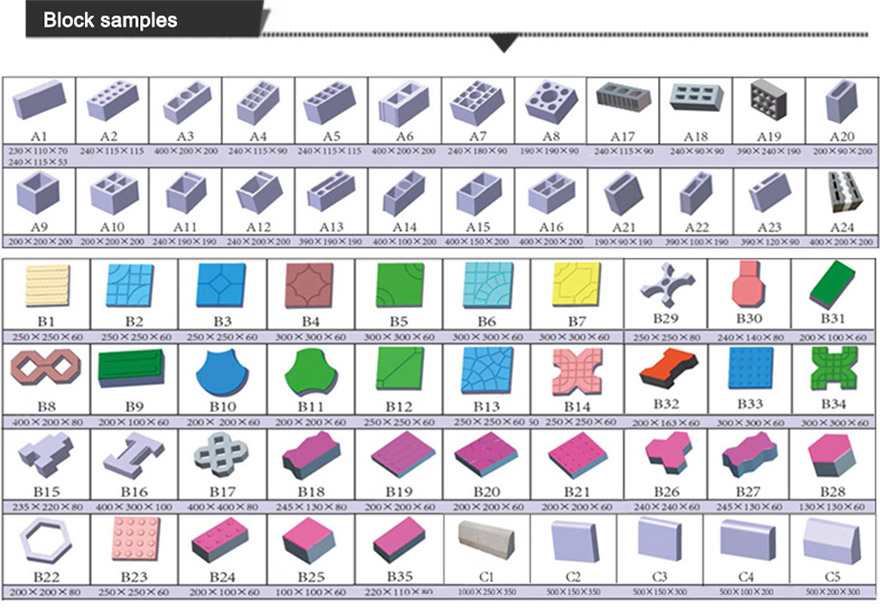

Block samples this machine can produce

The mould is customizable, and this machine can produce different kinds of blocks just by changing different mould.

Engineers are available for installation abroad

Our engineers can go to your country to help you install the machine, so don’t worry about the installation problem.