Description

▶ Main advantage of this hydraulic machine for interlocking bricks.

1.High efficiency: FL2-10 is a full automatic clay brick making plant production line. It can produce11520pcs/8h(for the size:300*150*100mm).

2.muti-function: FL2-10 soil cement block making machines can produce different compressed soil interlocking blocks just by changing moulds.

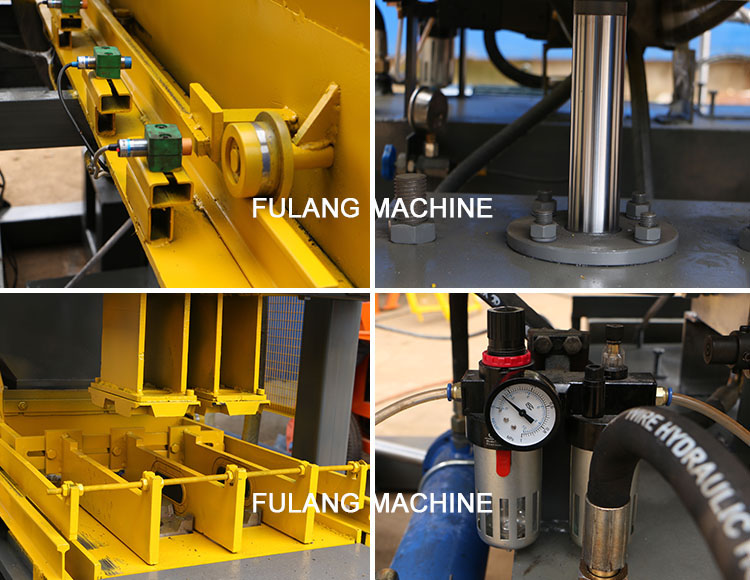

3.Advanced technology : Hydraulic moulding technology is adopted by this soil block making machine, so the blocks produced by this dirt brick machine are of large density and high strength.

4.Mold technology: In the production process of mould, we adopt precise wire cutting technology and carburizing heat treatment technology to confirm the mould has longer service life.

▶ Technical Parameter

| Dimension of host machine | 2200*1050*2200mm | Weight of host machine | 1300kg |

| Shaping cycle | 10s | Moulding method | Hydraulic pressure |

| Hydraulic pressure | 20 tons | Voltage | Adjustable/suitable to local voltage |

| Products | soil Interlocking bricks | Worker needed | 3-4 persons |

| Mould production technology | Heat treatment | Certification | CE&ISO |

▶ Packaging and delivery