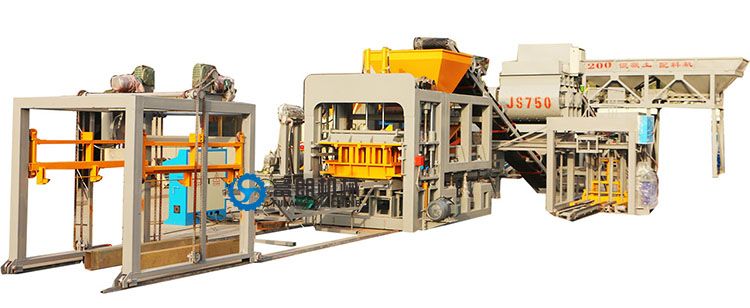

1. Hydraulic brick making machine

Automatic hydraulic brick machine is a professional non burning brick making machine upgraded and improved on the basis of hydraulic brick machine. Relying on hydraulic power source and simple touch screen. Double-sided pressure full-automatic hydraulic block machine operation, the automation and intelligence can be realized. It is better than the common hydraulic block making machine and the non burning machine in the brick production rate and quality. The performance of the automatic hydraulic machine is comparable to the similar products of the United States and Germany, but its price is 1/3 of that of the similar products.

Hydraulic machine uses hydraulic power to make bricks. It is also necessary to distinguish non burning machines which rely on mechanical vibration to make bricks. But do not think that the hydraulic machine does not need vibration, all brick making machines rely on vibration to make the raw materials fully combined. Generally, the hydraulic brick making equipment is larger than the mechanical vibration, the price also varies a lot, in the brick speed and quality is much better than the mechanical, but also can not be generalized. But the hydraulic machine, especially the large-scale hydraulic press brick machine, has become the mainstream, and has the experience of foreign machine development for reference.

2. Models of hydraulic brick making machine

Hydraulic block model includes qtf4-25, qtf6-15 and qtf8-15, qtf10-15, qtf15-15 etc.

3. theoretical forming cycle

The theoretical forming cycle 15 seconds

4. Hydraulic performance of hydraulic brick press

The hydraulic performance of hydraulic brick press is mainly shown in the following aspects:

(1) Pre pressure

(2) Hydraulic seal and pipe fittings

(3) Working pressure of master cylinder

(4) Hydraulic oil leakage phenomenon: the hydraulic seal and pipe fittings of hydraulic brick machine are imported components, while the common brick machine adopts domestic components. The hydraulic oil leakage of the hydraulic brick press is slight, but the common brick passing machine will appear serious and the demoulding cylinder will burst frequently. The positioning accuracy of the billet machine and die sleeve of the hydraulic brick press is controlled within 2 mm, while that of the ordinary brick machine is more than 5 mm.

(5) The quality of brick making is good and the cost is low. Because the hydraulic brick making machine has high pressure and double and multi-stage pressure, its brick making effect is better than all kinds of non burning type. At the same time, because of its high pressing force, it can use less cement and other cementitious materials and admixtures. In addition, the cost of the non fired brick made by him is lower than that of the mechanical brick press due to the factors such as low reject rate, less manpower and power saving.

(6) Positioning accuracy of blank machine and die sleeve

(7) Because the hydraulic machine can achieve high forming pressure, it is difficult to achieve by mechanical brick making machine. Therefore, although its pressing action is slow, it can be realized by increasing the pressure tonnage. It can form dozens of bricks at a time, reaching a very high output of 100 million to 200 million standard bricks per year. At present, mechanical press can not achieve such a high output. Therefore, the hydraulic brick making machine is easy to realize large-scale and large-scale production, which makes up for its low working speed and has the advantage of high efficiency after large-scale.

5. Development direction

(1) It will develop in the direction of large tonnage, seriation and energy saving.

(2) Hydraulic system tends to be simple, the purpose is to save energy, reduce maintenance costs, and improve the suppression frequency.

(3) The structure is compact, the body deformation is small when pressing, and the quality of pressed brick is excellent.

(4) Pay attention to the different direction of the main cylinder, reduce the wear of the main parts and improve the pressing accuracy.

(5) With the development of multi-function, it can carry out secondary cloth pressing and composite one-time pressing molding of different materials.

(6) Pay attention to the uniformity of cloth to improve the quality of pressed brick.

(7) With the help of computer technology, the fault position of hydraulic press can be detected automatically, which is convenient for timely maintenance.

6. Safe operation of hydraulic non burning brick machine

(1) When the machine is running, all protective covers and ground covers must be installed.

(2) No one is allowed to stand in the direction of motor to avoid vehicle accident.

(3) Check the grounding wire of electrical part to avoid leakage and short circuit.

(4) When the brick block machine is not started, it is not allowed to start the feeding mechanism, so as to avoid damage to the blank parts due to overload.

(5) When the machine is found to be abnormal, stop the machine immediately to check and eliminate it.

7. Introduction of automatic hydraulic brick press

8. Performance advantages of automatic hydraulic bblock machine

The advantages of automatic hydraulic brick press are as follows: 1

(1) The full-automatic hydraulic brick press breaks the traditional press from top to bottom, instead of pressing from bottom to top, which overcomes the defects of the old press which are easy to punch and cause mold damage.

(2) The full-automatic hydraulic brick block machine adopts the control mode of internal displacement sensor, which is not affected by environmental pollution. It can ensure the external dimension of the brick accurately and make the product reach the national first-class brick standard. The machine is also equipped with an internal pressure sensor, which can accurately measure the strength of the brick.

(3) The full-automatic hydraulic brick press has good exhaust performance and can produce hollow brick continuously for a long time.