Description

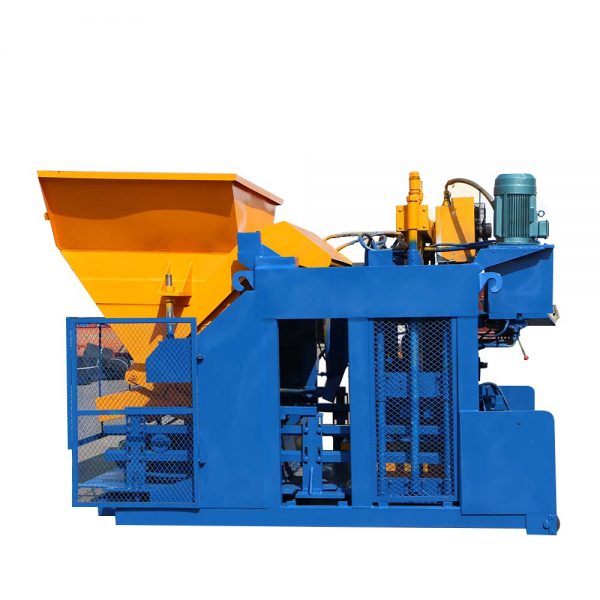

Egg laying hollow block machine 12000pcs per 8 hours

It is one mobile brick machine, based on foreign advanced technology and process, our company research and development mobile hydraulic brick machine, the brick machine has great advantage as follow:

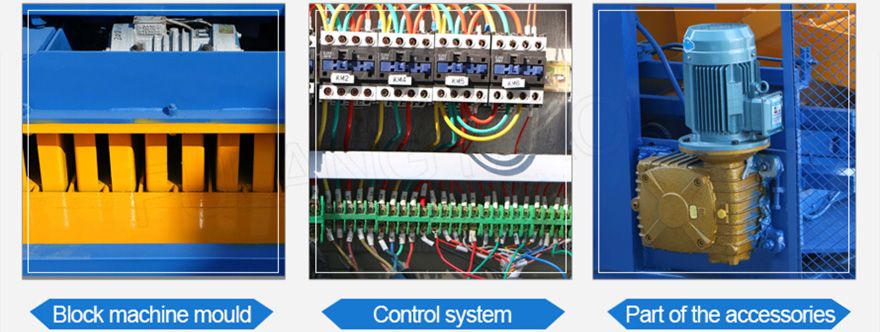

Technology advanced: the whole design process consider principle of integrative reconciliation and the internal structure of a rational order, so the machine have great technical advantage, it adopt several new technique, such as box excitation, hydraulic discharge, omnidirectional automatically movement

High quality: the whole machine is adopted high quality steel, and precision welding, the hydraulic system use high-quality components, so it have a longer life and less fault during work

Low investment, high efficiency: this machine have several function features, such as low price,reliable performance, easy to operated, stable, more efficient, high output, low power consumption. the brick it produced have high density, high strength, accurate dimensional, good appearance,so it can reduce the customer’s investment and production costs and give fast and large benefit

Main technical parameter of QT10-15 egg laying hollow concrete block molds for sale

| QT10-15 Mobile concrete hollow block machine brief introduction main technical parameters | |

| Overall dimension | 3150*1800*2400mm |

| Demold method | Hydraulic |

| Turning method | Hydraulic |

| Hydraulic system pressure | 16-20Mpa |

| Excitation frequency | 3200Hz |

| Total power | 16KW |

| Total mass | 4200KG |

| Molding cycle | 10-15S |

| Molding | 10 Pcs/mould(400*200*200/390*190*190 mm) |

| Capacity | 2000-9000Pcs/hour |

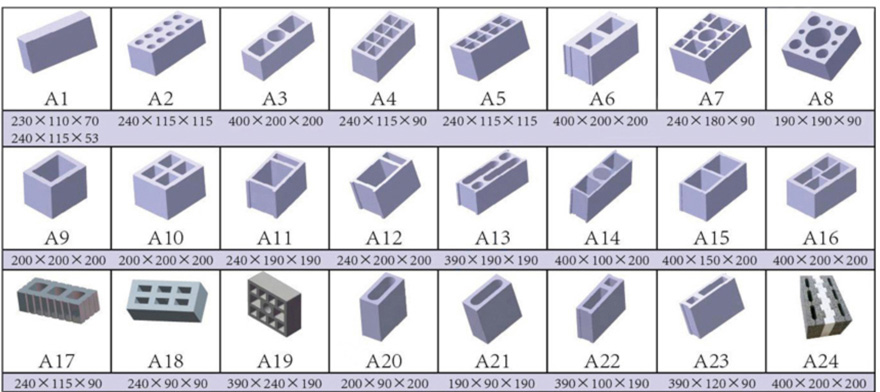

| Types of bricks can be made |

390*240*190/390*190*190/390*115*190 |

| Moving method | Automatically move and hydraulic steering |

| Excitation way | Three-dimensional box excitation |

| Raw material |

Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and |

Capacity of QT10-15 egg laying block making machine

| Brick size (mm)/(inch) | Pcs/mould | Pcs/hour |

| 530x100x200mm (20x4x8 inch) | 12 | 1728-2160 |

| 530x150x200mm (20x6x8 inch) | 8 | 1152-1440 |

| 530x200x200mm (20x8x8 inch) | 6 | 864-1080 |

| 400x100x200mm (16x4x8 inch) | 18 | 2592-3240 |

| 400x125x200mm (16x5x8 inch) | 14 | 2532-3360 |

| 400x150x200mm (16x6x8 inch) | 12 | 1728-2160 |

| 400x200x200mm (16x8x8 inch) | 10 | 1440-1800 |

This machine can produce different kinds of blocks just by changing mould, and the mould can be customized according to your requirement

Engineers will help you in your Country